H+E, one of the leading international designers and suppliers of industrial process and wastewater treatment systems, has received an order for a new biological wastewater treatment plant. Svilocell, a Bulgarian viscose pulp producer has to meet the future EU-imposed discharge limits into the River Danube. To achieve this, H+E will provide expansion by adding biological treatment to the existing purely mechanical wastewater treatment plant.

H+E’s Long Experience

Svilocell ultimately decided to work with H+E due to the company’s many years of expertise. We have designed and built nearly 80 plants for the pulp and paper industry. Those long-term customers have also expressed their very positive experiences! Another positive factor was that H+E’s design allows the new process steps to integrate compactly into the existing plant layout. This utilises the available space efficiently.

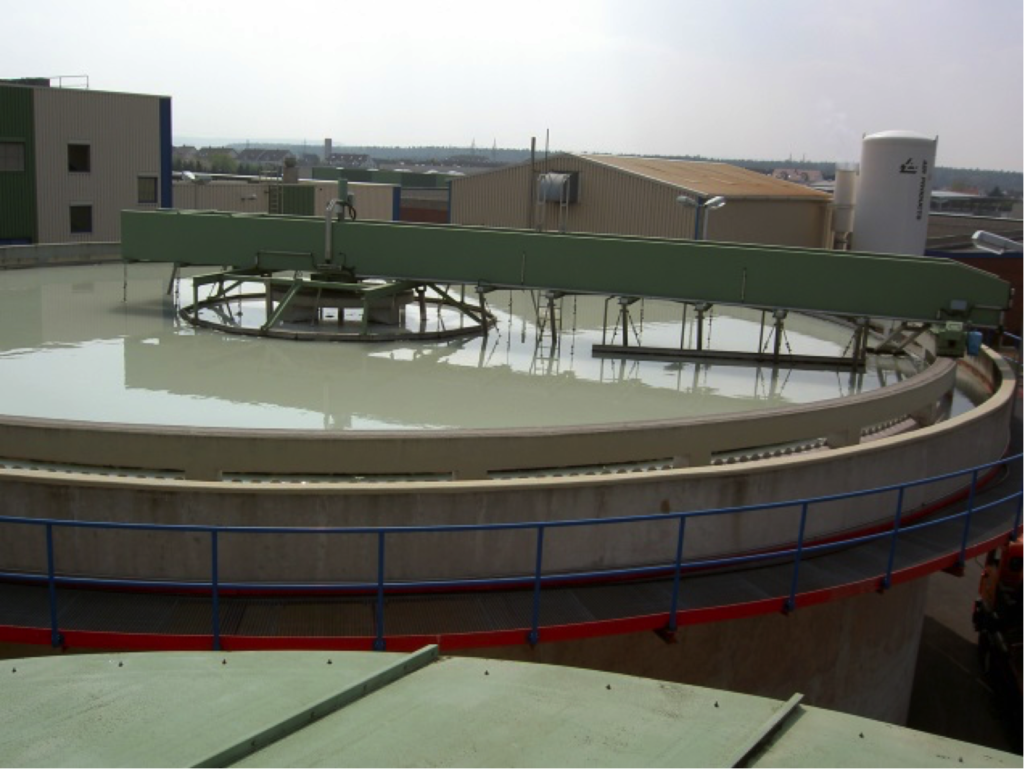

The wastewater is first cooled in an indirect cooling system to the temperature compatible with the biological process. A mechanical cleaning step then removes solids before the wastewater transfers to the new two-stage biological purification. The balanced combination of the BIOFIT®.H floating bed and the BIOFIT®.C aeration results in a cost-optimised solution.

In particular, the AEROFIT.V ventilation system contributes to the intrinsic value and energy efficiency of the new wastewater treatment system. It allows trouble-free operation over a period of decades with a consistently high oxygen yield.

Biochips with an especially high specific growth area are used as biofilm carriers.

The chosen process line will equip Svilocell with a highly robust and efficient wastewater treatment facility from 2018 onwards, in order to fully meet the requirements for environmental protection.

Wide range of available Technologies

H+E also offers other process technologies for the pulp and paper industry, such as the cost-effective and energy-efficient mechanical treatment FLOCOMAT®.T and, for tertiary treatment, the BIOFIT®.Oxyd2 or FLOCOPAC® processes to reduce resistant COD.

Long-Term Support

H+E has always offered Long-Term Technical Support, Servicing and Spare parts to every client. In many exceeds 25 years, demonstrating the long life of our designs. We also offer the same service to you if your plant was supplied by another company. Please just contact us and we will be happy to talk to you about your needs.